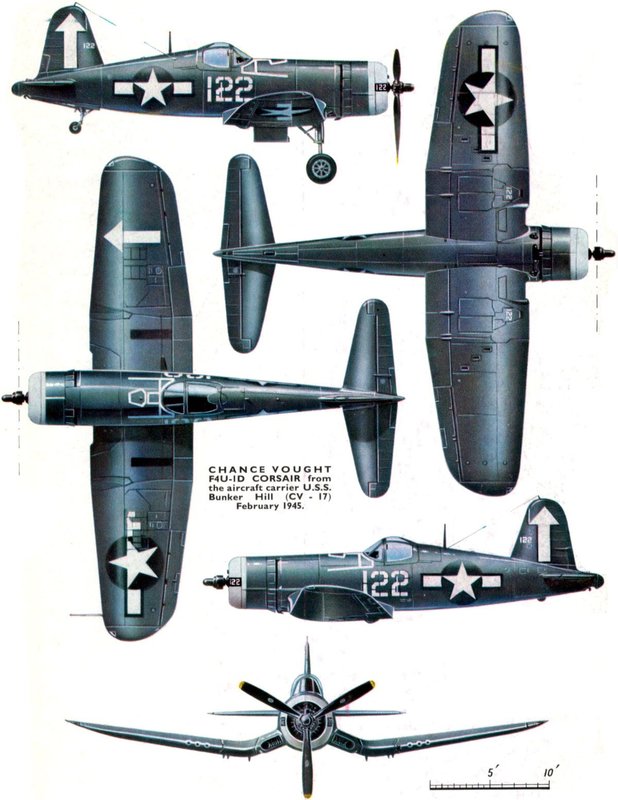

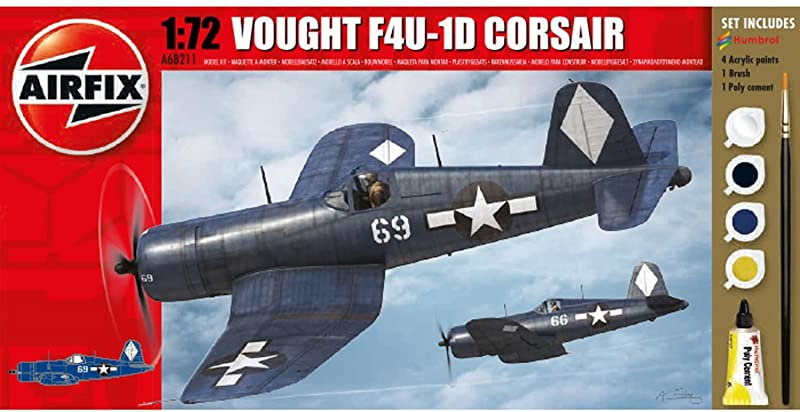

Airfix Vought-F4U-1D-Corsair-172-Military

Le Chance Vought F4U Corsair est un avion militaire américain, utilisé lors de la Seconde Guerre mondiale et jusqu'en 1968.

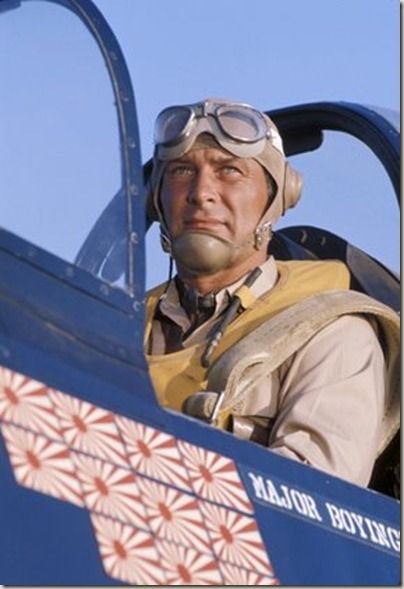

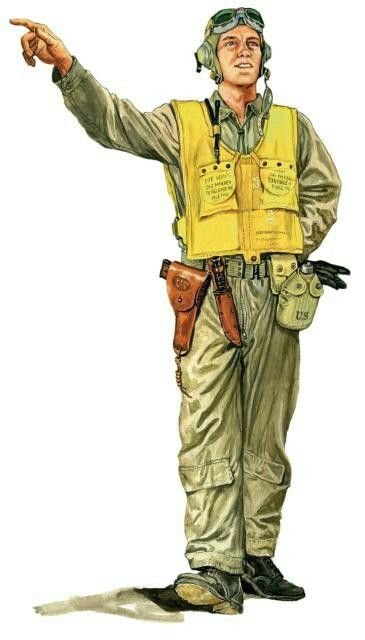

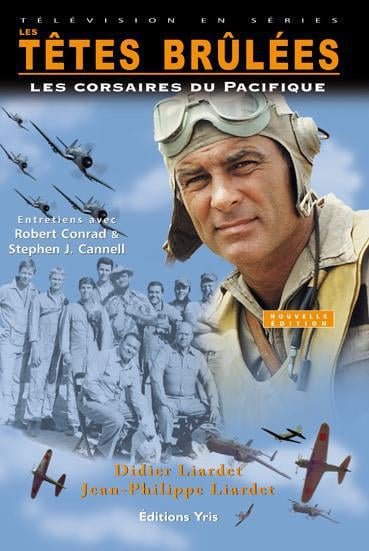

Il est l'un des appareils les plus connus de la Seconde Guerre mondiale, notamment grâce à la série télévisée Les Têtes brûlées, laquelle a popularisé sa silhouette trapue et son aile en W (aile en mouette inversée) qui rendent le Corsair presque immédiatement reconnaissable. Il s'illustra essentiellement dans le Pacifique, servant à la fois au sein de l'US Navy et de l'US Marine Corps Aviation.

Conception

La conception du Corsair débute en 1938 à la demande de l'US Navy qui voulait remplacer son chasseur embarqué, le Wildcat. Le projet, de l'ingénieur en chef Rex B. Beisel (en), est présenté le et le la Navy passe commande d'un prototype ; le premier vol du XF4U-1,BuNo 1443, piloté par Lyman Bullard (chef-pilote d'essais de Vought) a lieu le , sur l'aéroport de Bridgeport[1].

Le nom de « Corsair », reprend le nom du Vought O2U Corsair, un biplan conçu dans les années 1920. Le concept retenu par l'ingénieur étant de « concevoir le plus petit avion possible avec le plus gros moteur possible », le Corsair est dessiné autour de l'ensemble présentant la plus grande puissance disponible à l'époque (en dehors des moteurs de compétition), le R-2800 Double Wasp, doté d'un compresseur à deux étages et à deux vitesses, 18 cylindres en double étoile développant 1 850 ch au décollage, 1 460 ch à 6 550 m — le moteur est développé, depuis 1936, par Leonard S. Hobbs (en) et George J. Mead (en) chez Pratt & Whitney (entreprise appartenant au même groupe United Aircraft[2]).

L'hélice, mise au point par Hamilton Standard(autre société du groupe United Aircraft), mesurait 4,04 m de diamètre (la plus grande de l'époque). Ce diamètre d'hélice, et la nécessité d'avoir un train d'atterrissage assez solide pour apponter mais pas trop lourd et encombrant, amenèrent à choisir une voilure en W, ou « aile de mouette » inversée pour réduire la longueur du train. Avec un poids à vide estimé à 3 350 kg et une vitesse proche de 400 mph, soit 640 km/h, il était à l'époque supérieur à tout ce qui était à l'étude ailleurs dans le monde.

L'aile en W permettait aussi une faible trainée aérodynamique rendant inutile tout congé de raccordement, ce qui allégeait et simplifiait la construction. Le champ de vision du pilote, par cette position de l'aile, était accru à la fois devant et de chaque côté du nez. La voilure avait un profil NACA 2300 avec une épaisseur relative de 18 % à l'emplanture, 15 % à l'articulation des panneaux repliables (nécessaires pour l'utilisation sur porte-avions) et de 9 % aux bords marginaux. La partie fixe de la voilure avait des prises d'air de bord d'attaque pour alimenter les éléments annexes du moteur : refroidissement de l'huile, carburateur et compresseur. Cette partie de l'aile comprenait aussi un réservoir de carburant. Les trains d'atterrissage, placés au point le plus bas de la voilure, pivotaient de 87° en se rétractant vers l'arrière, la roue à plat au-dessus du bas de la jambe ; des trappes masquaient alors entièrement le train, pour la première fois dans un avion de l'US Navy.

Les panneaux extérieurs comprenaient des réservoirs mais aussi cinq compartiments par demi-aile pouvant recevoir chacun quatre bombes de 235 kg destinées à être larguées en mission d'appui au sol. L'armement prévu à la conception comprenait aussi deux mitrailleuses de 7,62 mm de capot et deux mitrailleuses de 12,7 mm (une dans chaque panneau extérieur) mais qui pouvaient éventuellement être remplacées par des canons Madsen de 23 mm.

Pour réduire la vitesse d’atterrissage, des volets hypersustentateurs à double surface et double courbure s'étendaient de l'emplanture à la moitié des panneaux repliables. Ce système était lourd et encombrant mais indispensable pour atterrir sur porte-avions.

Pour obtenir des surfaces plus lisses et diminuer le poids, la soudure par point (mis au point par Vought et la Naval Aircraft Factory pour l'aluminium) était utilisée. Seules les parties mobiles des gouvernes n'avaient pas de revêtement métallique mais étaient entoilées.

En novembre 1940, le Bureau of Aeronauticsmodifie le cahier des charges, demandant notamment le blindage et la protection des réservoirs et un renforcement de l'armement. Pour cela, la définition de l'appareil est revue :

- suppression de quatre des réservoirs de voilure (difficiles à protéger), ceux de la partie fixe de la voilure ;

- installation d'un réservoir de fuselage derrière le moteur ; pour cela il fallut reculer le poste de pilotage de 81 cm et avancer le moteur de 43 cm pour conserver un bon centrage. La visibilité vers l'avant en souffrit, mais celle du dessous fut augmentée puisque le pilote se trouvait désormais à la verticale du bord de fuite de l'aile ;

- les ailerons voient leur surface augmenter ;

- Les volets à doubles fentes sont remplacés par des volets à simple fente ;

- six mitrailleuses de 12,7 mm sont installées dans l'aile (trois par panneau extérieur) dotées de 400 coups pour les 4 intérieures, et 375 pour les deux les plus à l'extérieur.

La présentation du dossier définitif de l'avion de série eut lieu le [3].

The Vought F4U Corsair is an American fighter aircraft which saw service primarily in World War II and the Korean War. Designed and initially manufactured by Chance Vought, the Corsair was soon in great demand; additional production contracts were given to Goodyear, whose Corsairs were designated FG, and Brewster, designated F3A.

The Corsair was designed and operated as a carrier-based aircraft, and entered service in large numbers with the U.S. Navy in late 1944 and early 1945. It quickly became one of the most capable carrier-based fighter-bombers of World War II.[2] Some Japanese pilots regarded it as the most formidable American fighter of World War II and its naval aviators achieved an 11:1 kill ratio.[3][4] Early problems with carrier landings and logistics led to it being eclipsed as the dominant carrier-based fighter by the Grumman F6F Hellcat, powered by the same Double Wasp engine first flown on the Corsair's initial prototype in 1940.[5] Instead, the Corsair's early deployment was to land-based squadrons of the U.S. Marine Corps and U.S. Navy.[6]

The Corsair served almost exclusively as a fighter-bomber throughout the Korean War and during the French colonial wars in Indochinaand Algeria.[7] In addition to its use by the U.S. and British, the Corsair was also used by the Royal New Zealand Air Force, French Naval Aviation, and other air forces until the 1960s.

From the first prototype delivery to the U.S. Navy in 1940, to final delivery in 1953 to the French, 12,571 F4U Corsairs were manufactured[8] in 16 separate models. Its 1942–1953 production run was the longest of any U.S. piston-engined fighter.[9][10][11]

Development

In February 1938 the U.S. Navy Bureau of Aeronautics published two requests for proposal for twin-engined and single-engined fighters. For the single-engined fighter the Navy requested the maximum obtainable speed, and a stalling speed not higher than 70 miles per hour (110 km/h). A range of 1,000 miles (1,600 km) was specified.[12] The fighter had to carry four guns, or three with increased ammunition. Provision had to be made for anti-aircraft bombs to be carried in the wing. These small bombs would, according to thinking in the 1930s, be dropped on enemy aircraft formations.

In June 1938, the U.S. Navy signed a contract with Vought for a prototype bearing the factory designation V-166B,[13] the XF4U-1, BuNo 1443. The Corsair design team was led by Rex Beisel. After mock-up inspection in February 1939, construction of the XF4U-1 powered by an XR-2800-4 prototype of the Pratt & Whitney R-2800 Double Wasp twin-row, 18-cylinder radial engine, rated at 1,805 hp (1,346 kW) went ahead quickly, as the very first airframe ever designed from the start to have a Double Wasp engine fitted for flight.[14] When the prototype was completed it had the biggest and most powerful engine, largest propeller, and probably the largest wing on any naval fighter to date.[15] The first flight of the XF4U-1 was made on 29 May 1940, with Lyman A. Bullard, Jr. at the controls. The maiden flight proceeded normally until a hurried landing was made when the elevator trim tabs failed because of flutter.[16][17]

On 1 October 1940, the XF4U-1 became the first single-engine U.S. fighter to fly faster than 400 mph (640 km/h) by flying at an average ground speed of 405 mph (652 km/h) from Stratford to Hartford.[18] The USAAC's twin engine Lockheed P-38 Lightning had flown over 400 mph in January–February 1939.[19]The XF4U-1 also had an excellent rate of climb although testing revealed some requirements would have to be rewritten. In full-power dive tests, speeds of up to 550 mph (890 km/h) were achieved, but not without damage to the control surfaces and access panels and, in one case, an engine failure.[20] The spin recovery standards also had to be relaxed as recovery from the required two-turn spin proved impossible without resorting to an anti-spin chute.[19] The problems clearly meant delays in getting the design into production.

Reports coming back from the war in Europe indicated an armament of two .30 in (7.62 mm) synchronized engine cowling-mount machine guns, and two .50 in (12.7 mm) machine guns (one in each outer wing panel) was insufficient. The U.S. Navy's November 1940 production proposals specified heavier armament.[21] The increased armament comprised three .50 caliber machine guns mounted in each wing panel. This improvement greatly increased the ability of the Corsair to shoot down enemy aircraft.

Formal U.S. Navy acceptance trials for the XF4U-1 began in February 1941. The Navy entered into a letter of intent on 3 March 1941, received Vought's production proposal on 2 April, and awarded Vought a contract for 584 F4U-1 fighters, which were given the name "Corsair" – inherited from the firm's late-1920s Vought O2U naval biplane scout which first bore the name – on 30 June of the same year. The first production F4U-1 performed its initial flight a year later, on 24 June 1942.[22][23] It was a remarkable achievement for Vought; compared to land-based counterparts, carrier aircraft are "overbuilt" and heavier, to withstand the extreme stress of deck landings.

Design

The F4U incorporated the largest engine available at the time, the 2,000 hp (1,500 kW) 18-cylinder Pratt & Whitney R-2800 Double Wasp radial. To extract as much power as possible, a relatively large Hamilton StandardHydromatic three-blade propeller of 13 feet 4 inches (4.06 m) was used.

To accommodate a folding wing the designers considered retracting the main landing gear rearward but, for the chord of wing that was chosen, it was difficult to make the landing gear struts long enough to provide ground clearance for the large propeller. Their solution was an inverted gull wing, which considerably shortened the required length of the struts.[24]The anhedral of the wing's inboard section also permitted the wing and fuselage to meet at the optimum angle for minimizing drag, without using wing root fairings.[24] The bent wing was heavier and more difficult to construct, however, offsetting these benefits.

The Corsair's aerodynamics were an advance over those of contemporary naval fighters. The F4U was the first U.S. Navy aircraft to feature landing gear that retracted into a fully enclosed wheel well. The landing gear oleo struts—each with its own strut door enclosing it when retracted—rotated through 90° during retraction, with the wheel atop the lower end of the strut when retracted. A pair of rectangular doors enclosed each wheel well, leaving a streamlined wing.[25] This swiveling, aft-retracting landing gear design was common to the Curtiss P-40 (and its predecessor, the P-36), as adopted for the F4U Corsair's main gear and its erstwhile Pacific War counterpart, the Grumman F6F Hellcat. The oil coolers were mounted in the heavily anhedraled inboard section of the wings, alongside the supercharger air intakes, and used openings in the leading edges of the wings, rather than protruding scoops. The large fuselage panels were made of aluminum[26] and were attached to the frames with the newly developed technique of spot welding, thus mostly eliminating the use of rivets. While employing this new technology, the Corsair was also the last American-produced fighter aircraft to feature fabric as the skinning for the top and bottom of each outer wing, aft of the main sparand armament bays, and for the ailerons, elevators, and rudder. The elevators were also constructed from plywood.[27] The Corsair, even with its streamlining and high speed abilities, could fly slowly enough for carrier landings with full flap deployment of 50°.

In part because of its advances in technology and a top speed greater than existing Navy aircraft, numerous technical problems had to be solved before the Corsair entered service. Carrier suitability was a major development issue, prompting changes to the main landing gear, tail wheel, and tailhook. Early F4U-1s had difficulty recovering from developed spins, since the inverted gull wing's shape interfered with elevator authority. It was also found where the Corsair's left wing could stall and drop rapidly and without warning during slow carrier landings.[28] In addition, if the throttle were suddenly advanced (for example, during an aborted landing) the left wing could stall and drop so quickly that the fighter could flip over with the rapid increase in power.[29] These potentially lethal characteristics were later solved through the addition of a small, 6 in (150 mm)-long stall strip to the leading edge of the outer right wing, just outboard of the gun ports. This allowed the right wing to stall at the same time as the left.[30]

Other problems were encountered during early carrier trials. The combination of an aft cockpit and the Corsair's long nose made landings hazardous for newly trained pilots because of the lack of visibility due to said features. During landing approaches, it was found that oil from the opened hydraulically-powered cowl flapscould spatter onto the windscreen, severely reducing visibility, and the undercarriage oleo struts had bad rebound characteristics on landing, allowing the aircraft to bounce down the carrier deck.[30] The first problem was solved by locking the top cowl flaps in front of the windscreen down permanently, then replacing them with a fixed panel. The undercarriage bounce took more time to solve, but eventually a "bleed valve" incorporated in the legs allowed the hydraulic pressure to be released gradually as the aircraft landed. The Corsair was not considered fit for carrier use until the wing stall problems and the deck bounce could be solved.

Meanwhile, the more docile and simpler-to-build F6F Hellcat had begun entering service in its intended carrier-based use. The Navy wanted to standardize on one type of carrier fighter, and the Hellcat, while slower than the Corsair, was considered simpler to land on a carrier by an inexperienced pilot and proved to be successful almost immediately after introduction. The Navy's decision to choose the Hellcat meant that the Corsair was released to the U.S. Marine Corps. With no initial requirement for carrier landings, the Marine Corps deployed the Corsair to devastating effect from land bases. Corsair deployment aboard U.S. carriers was delayed until late 1944, by which time the last of the carrier landing problems, relating to the Corsair's long nose, had been tackled by the British.[N 1]

Production F4U-1s featured several major modifications from the XF4U-1. A change of armament to six wing-mounted .50 in (12.7 mm) M2 Browning machine guns (three in each outer wing panel) and their ammunition (400 rounds for the inner pair, 375 rounds for the outer)[32] meant the location of the wing fuel tanks had to be changed. In order to keep the fuel tank close to the center of gravity, the only available position was in the forward fuselage, ahead of the cockpit. Accordingly, as a 237 US gal (897 l) self-sealing fuel tankreplaced the fuselage mounted armament, the cockpit had to be moved back by 32 in (810 mm) and the fuselage lengthened.[24]Later on, different variants of the F4U were given different armaments. While most Corsair variants had the standard armament of six .50 caliber M2 Browning machine guns, some models (like the F4U-1C) were equipped with four 20 millimeter M2 cannons for its main weapon. While these cannons were more powerful than the standard machine guns, they were not favored over the standard loadout. Only 200 models of this particular Corsair model were produced, out of the total 12,571. Other variants were capable of carrying mission specific weapons such as rockets and bombs. The F4U was able to carry up to a total of eight rockets, or four under each wing. It was able to carry up to four thousand pounds of explosive ordnance. This helped the Corsair take on a fighter bomber role, giving it a more versatile role as a ground support aircraft as well as a fighter.[33] In addition, 150 lb (68 kg) of armor plate was installed, along with a 1.5 in (38 mm) bullet-proof windscreen which was set internally, behind the curved Plexiglaswindscreen. The canopy could be jettisoned in an emergency, and half-elliptical planform transparent panels, much like those of certain models of the Curtiss P-40, were inset into the sides of the fuselage's turtledeck structure behind the pilot's headrest, providing the pilot with a limited rear view over his shoulders. A rectangular Plexiglas panel was inset into the lower center section to allow the pilot to see directly beneath the aircraft and assist with deck landings.[N 2] The engine used was the more powerful R-2800-8 (B series) Double Wasp which produced 2,000 hp (1,500 kW). On the wings the flaps were changed to a NACAslotted type and the ailerons were increased in span to increase the roll rate, with a consequent reduction in flap span. IFFtransponder equipment was fitted in the rear fuselage. These changes increased the Corsair's weight by several hundred pounds.[34]

The performance of the Corsair was superior to most of its contemporaries. The F4U-1 was considerably faster than the Grumman F6F Hellcat and only 13 mph (21 km/h) slower than the Republic P-47 Thunderbolt.[35][36][37] All three were powered by the R-2800. But whereas the P-47 achieved its highest speed at 30,020 feet (9,150 m) with the help of an intercooled turbocharger,[38] the F4U-1 reached its maximum speed at 19,900 ft (6,100 m)[39] using a mechanically supercharged engine.[40]

/http%3A%2F%2Fstorage.canalblog.com%2F96%2F00%2F1123093%2F134247667_o.jpeg)

/http%3A%2F%2Fstorage.canalblog.com%2F06%2F82%2F1123093%2F134235267_o.jpeg)

/http%3A%2F%2Fstorage.canalblog.com%2F63%2F65%2F1123093%2F134214755_o.jpeg)

/http%3A%2F%2Fstorage.canalblog.com%2F80%2F34%2F1123093%2F134214751_o.jpeg)